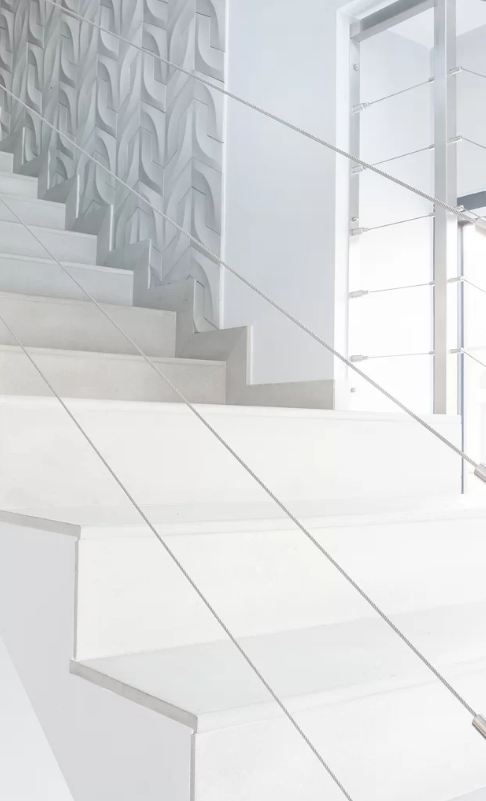

Concrete stairs with steps and risers, made to order for a high-end architectural concrete project. The technology of architectural concrete allows you to avoid the effect of joining and rubbing, and concrete stairs give the impression of monolithic ones. Thanks to the technology, concrete stairs have the highest frost resistance (expected from bridge structures). Concrete steps stairs can be successfully used both inside and outside. As an addition, it is possible to manufacture cladding for all finishing steps, landings according to individual projects. Often, the design uses a material that combines forms with metal and glass. Thanks to the strength of 8 MPa (for comparison, standard architectural concrete has a strength of 3.5 MPa), concrete stairs will last for many years. Of course, the execution of architectural steps from concrete gives the effect of a monolith of concrete stairs. In this solution, tread and riser are one element. They are placed on cast monolithic concrete stairs to give them the quality of an architectural concrete staircase. The thickness of the cladding depends on the area of application, but the main elements have a thickness of 2 cm. Thanks to this cladding of concrete stairs , designed from another material, can be replaced with architectural concrete without additional chipping and deepening of the surface. You can apply an interesting concept of connecting the handrails of concrete stairs with glass. Many types of handrails can be used for concrete stairs . The strength of the facing made of architectural concrete made of fiberglass allows drilling and loading of railing structures without problems. The standard finish of the stair step surface is smooth. The risers for elements of carpet steps in the standard configuration have variable porosity, which is technologically regulated. In that case, if the project includes elements of the standard, for example, slightly porous, this is not a problem. Thanks to their complete frost resistance, these elements are also used in open spaces. The material also has a satisfactory anti-slip performance, and in special cases it is also possible to make special perforations or to etch the surface. The dimensions of the manufactured elements are adjusted each time according to the needs of implementation, more cost-effective, cut on the construction site according to your needs. According to the technology, architectural hcc concrete does not contain crumbs of large fractions. This allows for easy cutting without the risk of damaging the edge. The elements are available in colors from white to black.